1

/

of

1

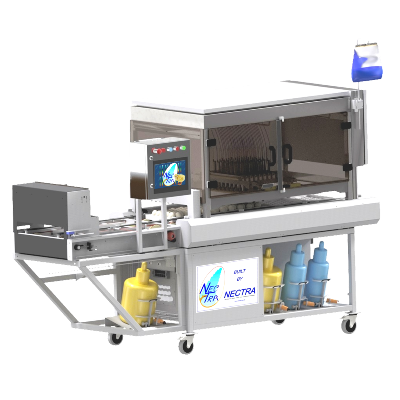

Inovovac: inovo vaccination

Inovovac: inovo vaccination

1. Functional design and structure

- Fully automated, NECTRA INOVOVAC is designed to carry out an accurate egg vaccination on defined specific trays. It may be used as stand alone or associated with NECTRA Candling Technology to remove unwanted eggs

- Only good eggs are vaccinated individually

- Control unit: Touch screen display ; USB connection for data transfer / HMI ; Automated data collection & data storage (by batch)

2. Equipment sizes & speed options

- HIGH SPEED version, fully automated, above 70 000 eggs/h, custom built to setter tray system

- COMPACT version, fully automated, 45 000 to 70 000 eggs/h according to type of tray

3. Technical specification and advantages

- Vaccine savings: 4 levels of vaccine saving

- No priming required

- Detection of missing & bad eggs

- Individual injection of selected good eggs

- Low pressure technology insuring integrity of vaccination potency

- Management of small batches of eggs by the electronic pilot

- Very little vaccine losses through reduced tube length and by using the vaccine saving program for small batches of eggs

- The V.I.S.A. Technology minimizes contamination risks during and after injection

4. Superior sanitation protection and contamination prevention: 5 levels of bacteria control

- Egg shell disinfection prior to injection

- Only good eggs are injected

- Needle disinfection between each injection

- Inovovac machine has automated disinfection and washing after production cycles

- Custom adjustment of disinfection timing and cycle through electronic management

- Fully automated, NECTRA INOVOVAC is designed to carry out an accurate egg vaccination on defined specific trays. It may be used as stand alone or associated with NECTRA Candling Technology to remove unwanted eggs

- Only good eggs are vaccinated individually

- Control unit: Touch screen display ; USB connection for data transfer / HMI ; Automated data collection & data storage (by batch)

2. Equipment sizes & speed options

- HIGH SPEED version, fully automated, above 70 000 eggs/h, custom built to setter tray system

- COMPACT version, fully automated, 45 000 to 70 000 eggs/h according to type of tray

3. Technical specification and advantages

- Vaccine savings: 4 levels of vaccine saving

- No priming required

- Detection of missing & bad eggs

- Individual injection of selected good eggs

- Low pressure technology insuring integrity of vaccination potency

- Management of small batches of eggs by the electronic pilot

- Very little vaccine losses through reduced tube length and by using the vaccine saving program for small batches of eggs

- The V.I.S.A. Technology minimizes contamination risks during and after injection

4. Superior sanitation protection and contamination prevention: 5 levels of bacteria control

- Egg shell disinfection prior to injection

- Only good eggs are injected

- Needle disinfection between each injection

- Inovovac machine has automated disinfection and washing after production cycles

- Custom adjustment of disinfection timing and cycle through electronic management

Keywords

- Egg vaccination

- Injection

- Automated

- Egg

About

NECTRA

NECTRA develops, designs, manufactures and supplies a complete range of robust and innovative industrial equipment for hatchery automation and pharmaceutical laboratories producing egg based vaccines. We also offer complete solutions for specific or turnkey projects adapted to all incubator suppliers.

Discover more about NECTRA

Related products and services

- Choosing a selection results in a full page refresh.

- Opens in a new window.

Get in touch

Your are interested by: NECTRA - Inovovac: inovo vaccination

Get in touch

Your are interested by: Inovovac: inovo vaccination